Maxxon Steel Pipe

Electric Resistance Welded (ERW) pipes are high-quality steel pipes formed by cold-forming steel coils into cylindrical shapes. The edges are then welded together using electric resistance welding, resulting in a strong, seamless bond. ERW pipes are widely used for conveying fluids and gases, as well as for structural applications across various industries. Our pipes and tubes are passed in engineering and autoparts products. We make customised sizes as per order .

Features of Maxxon Steel Pipes

High Strength and Durability

ERW pipes are known for their robustness and long service life, making them suitable for high-pressure applications.

Precision and Consistency

The manufacturing process ensures uniform wall thickness and diameter, providing reliability in various applications.

Cost-Effective Production

The efficient manufacturing process results in lower production costs, offering an economical choice without compromising quality.

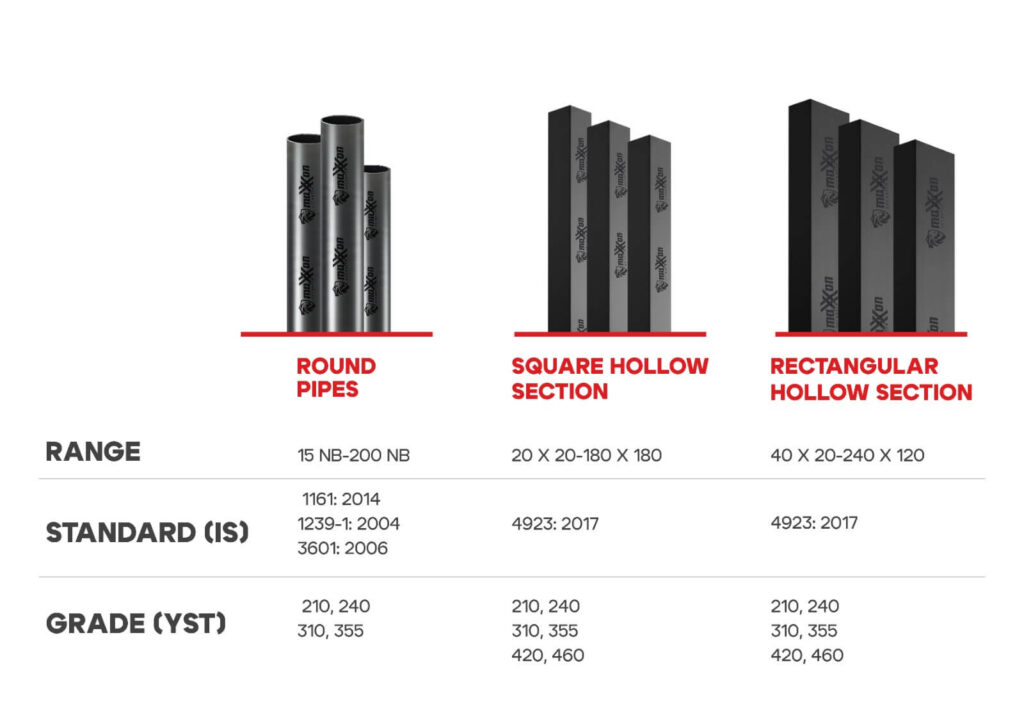

Versatile Shapes and Sizes

Available in round, square and rectangular cross-sections with a range of dimensions to meet diverse requirements.

Why Choose Us

We employ state-of-the-art manufacturing processes, including the latest quenching and self-tempering techniques, to produce ERW Pipes of unparalleled quality.

Our products undergo rigorous testing at every production stage, ensuring compliance with national and international standards.

We offer a wide range of grades and sizes to meet specific project requirements, providing flexibility and convenience to our clients.

Committed to environmental responsibility, our manufacturing processes are designed to minimize carbon footprint and promote sustainability with the help of state-of-the- art Equipment.

- 1. Uncoiling and Leveling

- 2. Forming

- 3. Welding

- 4. Sizing and Shaping

- 5. Cutting

- 6. Inspection and Testing

Steel coils are uncoiled and flattened to prepare for forming.

The flattened steel is gradually shaped into a cylindrical form through a series of rollers.

The edges of the formed cylinder are heated and fused together using electric resistance welding, creating a strong seam without the need for filler material.

The welded pipe passes through sizing rollers to achieve precise dimensions and desired cross-sectional shapes (round, square, or rectangular).

Pipes are cut to the required lengths as per customer specifications.

Each pipe undergoes rigorous quality checks, including non-destructive testing, to ensure compliance with industry standards.

Applications of Maxxon Steel Pipes

Construction Industry

Used for structural support, scaffolding, and building columns.

Oil and Gas Sector

Employed in the transportation of oil, gas, and other fluids.

Automotive Industry

Used in making vehicle parts like exhaust systems.

Agriculture and Irrigation

Utilized in water supply systems, drainage, and irrigation infrastructure.

Furniture Manufacturing

Used in creating durable frames for furniture and equipment.

Telecommunications

Ideal for installing communication lines and cables, ensuring protection.

ERW Black & Galvanized Steel Pipes & Tubes